Science for firm steps

Behind great flooring, there is high technology work in several areas of the industry. Innovation takes place in four scenarios: the laboratory to experiment and create the optimum chemical formula for each project, the R&D workshop to have the best precision flooring machinery and, thirdly, the project execution site to use the most sophisticated laser equipment to produce High Planimetry. The fourth scenario cannot be seen during the project. It starts many weeks, or even months, beforehand: it is the planning of industrial logistics on a major scale. As we know, concrete has a 'tempo', a specific speed to obtain the perfect chemical process, and this involves a planning of supplies that has to be repeated for weeks in specific quantities. This involves the analysis of suppliers, creation of transport routes by sea and land, preparation of fleets on an extraordinary scale. For the A Laracha technological paving, for example, raw materials with a weight equivalent to 1,100 cars had to enter each day (and uninterruptedly for 90 days). And all of this in the indicated proportions and times.

The three pillars of innovation in Prosistemas

Types of flooring

The laboratory of Prosistemas has patented several ‘intelligent’ floorings –cementitious or designed with polymers /resins- with unique customisable properties.

Perfected machinery

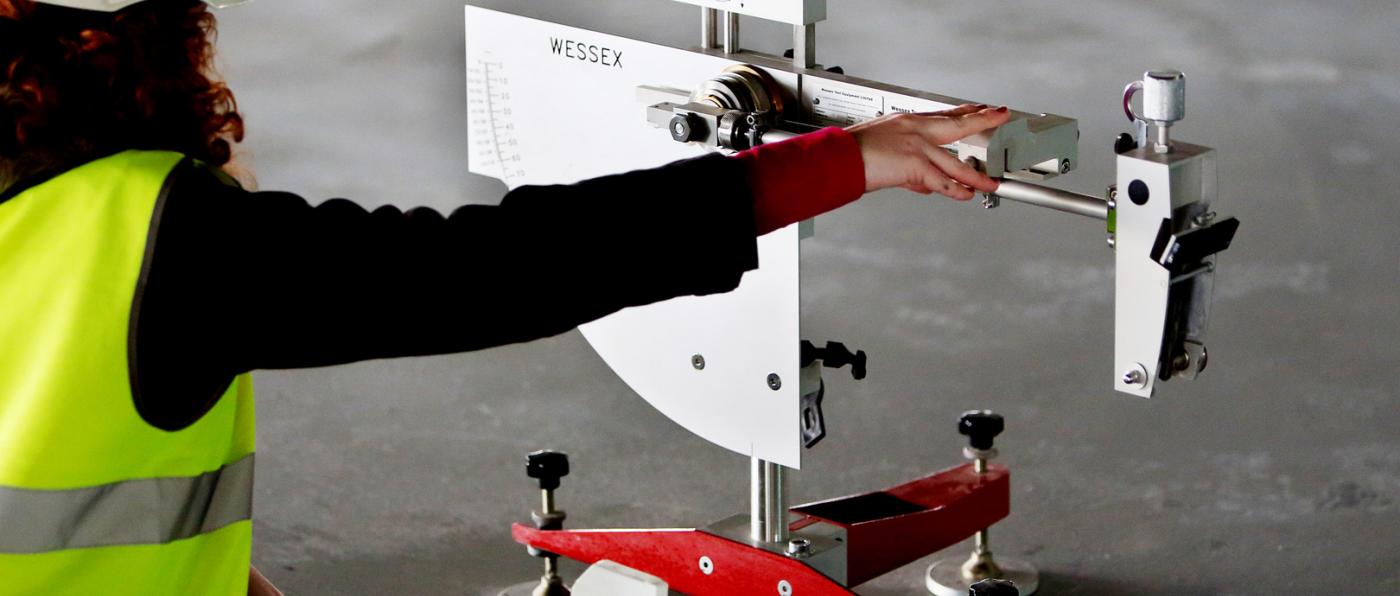

Despite using the most advanced machinery on the market, engineers in Prosistemas, in collaboration with universities, have perfected conventional equipment. We use state of the art and proprietary designed equipment and robots.

Planimetry

Laser levelling systems. Production machinery guided by the laser system: Dipstick Digital Inclinometer.

How do you measure quality in Planimetry?

To make a small flooring flat is relatively easy, but to do the same on a large scale, maintaining regularity of the floor for thousands and thousands of square metres is a mathematical and construction challenge, both in theory and practice. The international ‘F numbers’ table classifies the planimetry of flooring by two criteria: flatness and levelling. In the following graph of an average flooring built by Prosistemas for a large commercial area, we can see that our product exceeds international classification standards for this type of surface.

International ASTM table to classify the regularity of flooring. This is the so-called ‘F numbers’ system, a mathematical calculation that evaluates flatness and levelling

– Types os surface –

The flatter the floor, the higher vertical storage can go

This approximation to the perfect floor has immense and long-lasting benefits for companies that operate vertically, with high-rise storage installations that remain constantly perpendicular to the ground and facilitating the work of elevating mechanisms and forklifts. High storage avoids having to build many storeys in warehouses and the resulting traffic to move from one to another. Savings are enormous. A few millimetres error at the floor level can mean several unacceptable centimetres at a height of ten metres. Manufacturers of elevation and forklift systems operating at heights offer technical documentation on the planimetry conditions necessary for correct operation. To achieve these extremely high levels of quality, Prosistemas uses the most advanced measurement and levelling systems, starting with laser technology. The machinery used by our company to extend the flooring is networked, interconnected with the general laser system that supervises each square centimetre of the work surface. For this reason, when we make high planimetry flooring, two technical criteria must be taken into account:

Los dos criterios técnicos

para valorar la superficie perfecta

Flatness ( Ff )

The degree of approximation to the perfect geometrical plane. Without bulges, roughness, bumps or projections in the flooring.

The final phase of the execution of the work –with the polishing and treatment of the top layer - is the most important to obtain the maximum flatness.

El tramo final de la ejecución de la obra -con el pulido y el tratamiento de la última capa- es el más importante para obtener la máxima planeidad.

Levelling ( FL )

The degree of horizontality of a surface as a whole. A surface can be perfectly flat but sloping and vice versa.

The initial measurement work and placement of the shuttering and the steel reinforcement prior to pouring the concrete are decisive to obtain horizontality in a large surface.

Los trabajos iniciales de medición y colocación del encofrado y el armado de acero previo al hormigonado son decisivos para obtener la horizontalidad en una gran superficie.

What is an intelligent floor?

Intelligent floors are new laboratory-created flooring systems for very specific tasks, specialized and adapted to the needs of a specific activity. The initial materials are cementitious or polymer /resin based and have surprising characteristics, such as specific non-slip properties or a certain chemical resistance. In food industry, they will resist the daily aggression of cleaning products and disinfectants while at the same time being rot proof material that no liquid will penetrate (like a glass floor).

In military installations they will resist the passage of very heavy tracked vehicles and in a jeweller’s they will have to be as beautiful and shiny as a Fabergé egg. Flooring for an operating theatre must not produce dust or static electricity and in a shopping centre it must be able to resist impacts without getting scratched and will reflect a planned amount of ambient light to reduce maintenance costs and provide comfort. And on a sports track that can be deformed by impact, it will absorb the impact of a fall.

Prosistemas works with a dozen patents on materials and special coatings, such as hardeners to vitrify flooring and give it insulating, decorative sheen or ultra-resistance to chemical or mechanical aggression properties.

The finishing touch, Prosidur Diamond

The Prosidur Diamond system is one of the most successful Prosistemas products in the construction of large continuous flooring areas with high levelling and maximum durability. Its name derived from its shine and extreme hardness characteristics and it is used to finish an extremely high quality floor. This hardener offers enormous resistance to abrasion and all types of wear. It does not get scratched. This surface treatment drastically reduces maintenance and preservation costs, prolonging the life of the flooring and increasing ambient light. Its consistency enables the perfection of the final flatness of the floor, while at the same time bearing the traffic of heavy vehicles unscathed and absorbing part of the noise created by the traffic.